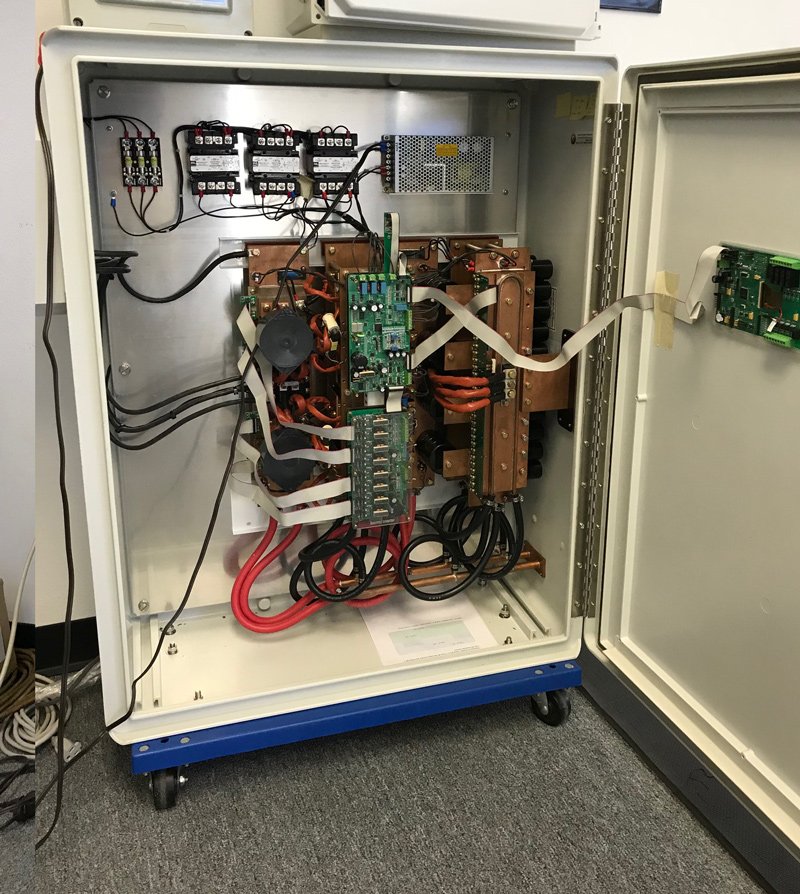

The key to any effective and correct electroplating system is the rectifier.

“A rectifier is the heart of the line,” Dan Dunigan said. “Without the right-sized and powered rectifier, much of the rest of the system and process is moot.”

Dan is the technical sales manager and an executive with A Brite Company, a leading provider of equipment and lab services to the metal plating industry. A Brite is based in Garland, Texas, with representatives worldwide.

Rectifiers regulate the power of the current between the anode and cathode that are at either end of the plating system. Depending on the system, they can range in size from a few microvolts to megawatts of power.

“The constant and consistent regulation of the power ensures the best results in the actual plating of the final product,” Dan continued.

For more information about how to choose the correct equipment, including rectifiers, for your plating line, please call Dan or his team at A Brite at 1-888-8-BRITE, or visit the website.

The Finishing Touch