Waste Water Treatment / Recycle & Reuse Systems

We provide both the components as well as whole waste recycle, reuse and treatment systems.

FLOW THROUGH TREATMENT SYSTEMS

A Brite Company Flow thru systems are designed to continuously treat industrial wastewater at 5 to 400 GPM. PLC based control panels prevent untreated discharge of Industrial and plating shop wastes such as Chrome and Cyanide. These systems with integrated clarifiers can replace much larger conventional multi tank installations.

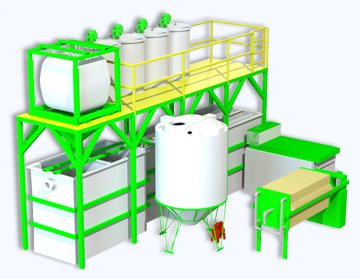

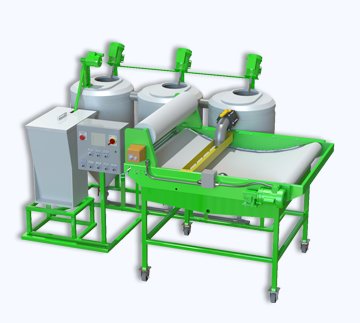

UNIVERSAL BATCH TREATMENT SYSTEMS

With capacities to 1,500 gallons per batch, these units treat wastewater contaminated with heavy metals, TSS, FOG, BOD, Etc, Utilizing a PLC based control panel, PH adjustment, ORP reduction, precipitation, flocculation, effluent filtration, and sludge to filter press all sequence automatically. The system is skid mounted for ease of shipping and installation, and includes either a two or four cubic foot filter press, and 5-micron final filtration.

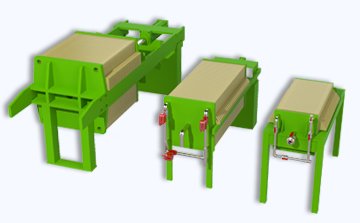

FILTER PRESSES

A Brite Company Filter Presses are utilized in a wide variety of high volume solids separation requirements. This Fabricated Design with bolted side rails allowing for expansion feature ribbed polypropylene, center feed, four-corner discharge plates and woven polypropylene filter clothes for high filtering efficiency. Air blow down manifold is standard equipment. Units are available in 470mm to 1500mm sizes. Automatic Side rail Mounted Plate Shifter option is available.

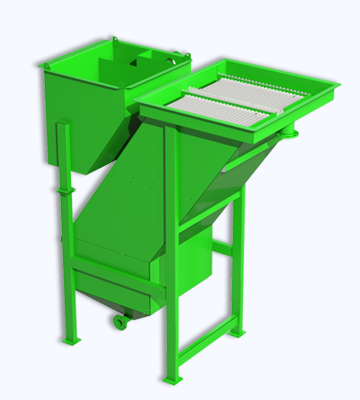

HIGH CAPACITY ANGLED PLATE CLARIFIERS

A Brite Company Clarifiers are the ideal choice for settling a wide range of precipitated waste streams. With include welded steel construction, built in large capacity flash mixing tanks, laminar flow conditions, and large sludge holding sections. Flows available from 5 to 500 Gallons per minute. These epoxy coated and lined units are built for long service. Pre and Post treatment modules are available.

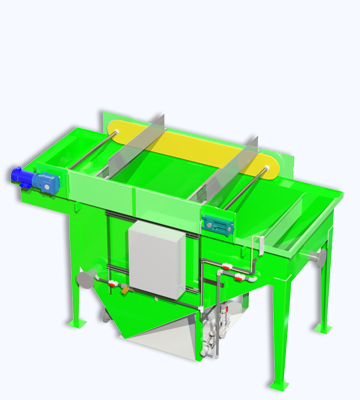

DAF (DISSOLVED AIR FLOTATION) SYSTEMS

A Brite Company DAF systems utilize the proven process of Dissolved Air Flotation, with Ultrafiltration technology for final polishing of effluent. These Hybrid systems are designed to treat waste streams normally considered too difficult for Membrane systems alone due to high oil and grease, and solids loading. The design allows for a much smaller footprint than conventional clarification/ separation systems and separate membrane post treatment. Nano-filtration and Reverse-Osmosis elements can also be utilized.

BENTONITE CLAY SYSTEMS

Bentonite clay-based wastewater treatment products remove Emulsified Oils, Metals and Suspended Solids. Bentonite works in a wide pH range, most applications require no pH adjustment. All reactions necessary for chemical treatment are packaged in the clay blend, which means only 1 tank is necessary to perform all treatment functions, reduce the amount of floor space, less pumps, valves and power are required, reduce the chances of mechanical failure and Simplified Operations. The process is a simple one step procedure, and can be accomplished by either manual or with completely automatic equipment. Blended Bentonite Clay is fast, the reaction takes from 1 to 5 minutes. No personnel are required during normal operations, which means your labor costs will drop dramatically. The clay encapsulates the contaminants, the resulting sludge is usually non-leachable & therefore non-hazardous, which means waste disposal costs will be reduced substantially.

Questions? Speak to an Expert today!

Company:

Resources:

Quick Links:

Stay up to date with A Brite Company

Enter your email address and we will keep you updated on our products and services.

© 2023 A Brite Company, Inc. All Rights Reserved.

© 2022 A Brite Company, Inc. All Rights Reserved.